ABOUT US

Posted on 24th November 2021 at 11:16

ABOUT US:

Hi,

Welcome to our new website! Thanks for stopping by.

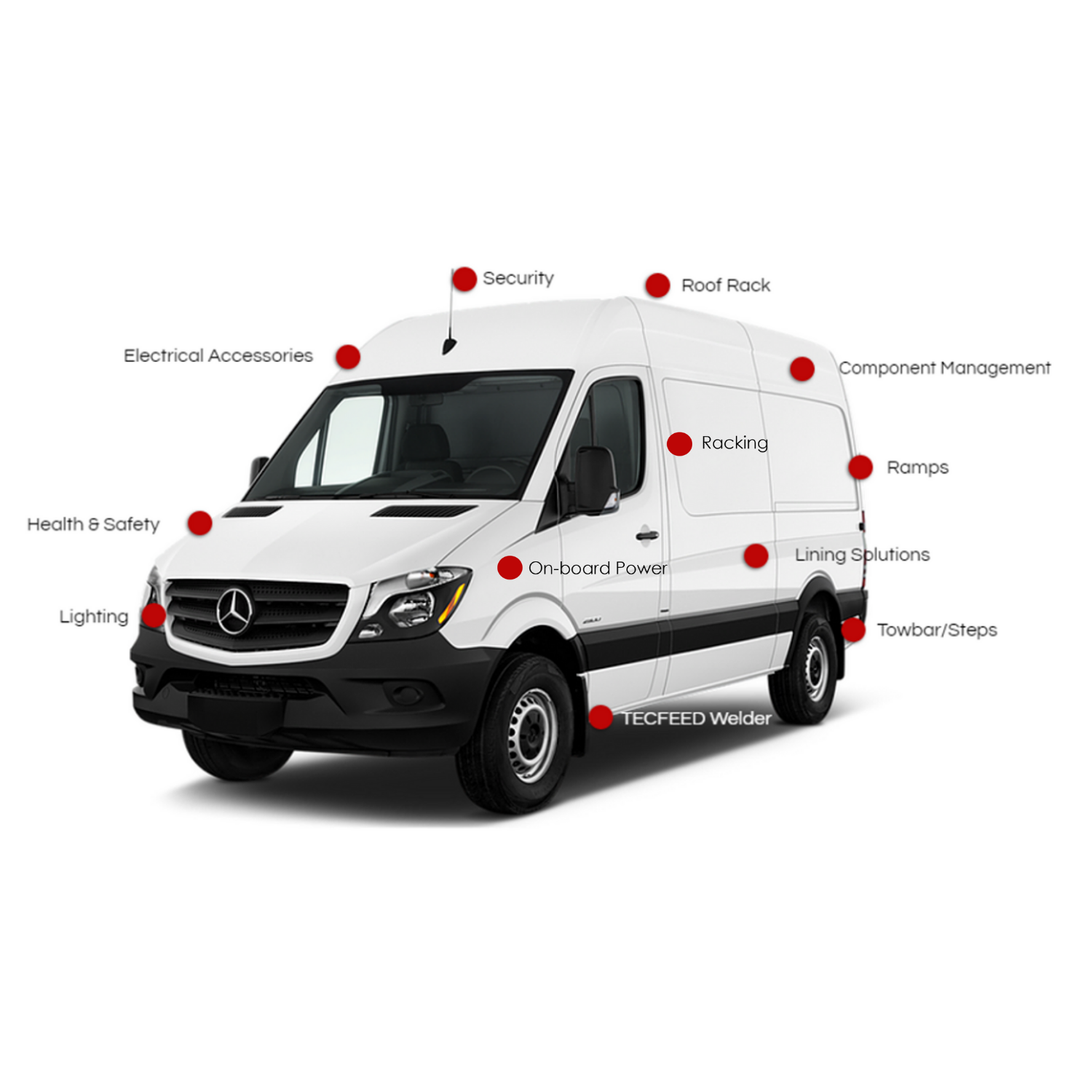

So, a bit about us…. Motor on Services was started back in 1997 by Phillip Butler. A professional engineer with a goal to create unique and well thought out conversions in the Commercial Motor trade. T he goals to be innovative, unique and accessible to any fleet size or budget whilst creating a line of product solely in the UK for the UK from dock to door.

With the help of some intelligent friends/colleagues was created the 1st item perfected my MOS, our Automate products this was designed to be a safe and reliable source of power wherever and whenever it is required. The system can be used for anything from welding and battery charging to lighting and electrical equipment. This product is still so popular today as it was sort of ahead of its time with the usage of environmentally friendly, re-usable power. This product is so durable it has outlasted the life span of the commercial fleet itself being able to be refitted 4-5 times in its 20 years in the field.

Key Features are:

• 110V AC C.T.E (Centre tapped earth)

• 3000W Power output (continuous rating)

• Safety Interlocks and Emergency Stop

• Each power line individually fused to earth

• Power Control Module • 55V DC Arc Welding (up to 150A)

• 12V Regulated battery charging (up to 150A)

• 24V Regulated battery charging (up to 150A)

• 12V/ 24V Boost Battery Charging (up to 150A)

• Lightweight and compact design (Full system 26KG)

It’s a product that has really stood the test of time.

We then went on to design solutions for rest of the vehicle and its requirements by our customers.

We wanted to offer more so then Autorack was made, we sourced a UK factory to sit down and bring the designs and drawings to life. This ever-growing product line is created with most components being interchangeable to create a complete unique racking system to suit the individual needs of the vehicles.

Key features are:

• Cold rolled mild steel construction

• Precision CNC Laser cut and punched profiles

• Fully automated conveyorized powder coating process

• Textured polyester powder coated finish, giving better scratch resistance

• Modular construction, giving ease of adaptability

• Specially designed robust flexible fixings system

We also have a wide range of accessories to apply the finishing touches to any conversion in our Autoaccessories line.

Key features are:

• TecFeed 250i Welding system

• Towbars/ Steps/ramps.

• Ply linning & Anti slip flooring

• Vehicle Lighting Solutions

• Shelf Storage Bins/ Service Cases/toolboxes

• COSHH Cabinets

• Roof Racks

• Slam Locks Deadlocks

• Reverse Alarms/ Cameras

• Health & Safety Accessories e.g. First aid kits.

In the last 20 years we have been able to grow our product line with the knowledge and confidence in any business sector from Plant to Healthcare. And are still just as passionate today as day 1 on providing a great conversion/product.

With the everchanging world of fleet and the new elements to be taken into consideration moving forward we have some exciting new products launching in 2022 that you should keep your eye out for.

Thanks for reading!

M.O.S